Innovation and Future

Stoneridge's ambition reaches beyond the present, looking towards the future. Stoneridge is at the forefront of adapting to changing safety needs worldwide. By blending smart technology with our in-depth industry knowledge, we design systems that anticipate and respond to potential hazards, making mining operations safer and more efficient. Our systems thus meet the highest quality standards and international norms. We're proud to play a key role with OEMs globally and continue to push the boundaries of technology and safety for both current and future mining challenges.

From Sight to Insight

For mining machines, optimal visibility is essential according to Stoneridge's vision. We work closely with OEMs worldwide to integrate our advanced camera-monitor systems. Designed with stringent quality requirements, these systems are robust and compact. They withstand extreme temperatures and are dust and waterproof (IP68 & IP69K), as well as shock and vibration resistant.

Find a dealer

Our Orlaco Vision System dealers are available in over 35 countries worldwide, ready to support you. Whether you need product information, technical help, or installation services, our dedicated dealers are here to assist. Reach out today and experience exceptional support!

Contact us

Is there something you would like to know or need our help with, but could not find on our website? We are here to help you! Please leave your contact information, and we will contact you as soon as possible.

Our Systems for Mining Machines

Below is a selection of the visibility solutions we offer for mining machines. Click on the visibility solution for your vehicle for more information.

Digital Multiview

Boost safety, remove blind spots, and give operators a full, real-time view of their surroundings with the advanced Digital MultiView system from Orlaco Vision Systems.

View-on-Forks

Enhance precision and safety when moving goods with the View-on-Forks camera system for forklifts. This advanced camera-monitor system from Stoneridge offers perfect visibility between the forks of a forklift or reach truck. The camera's positioning allows drivers to track both forks in real-time, enabling them to pick up pallets in one go. This increases safety in the warehouse and ensures more efficient goods handling.

Work More Accurately with View-on-Forks

With View-on-Forks, drivers can perform their work with greater accuracy and confidence. The camera is mounted between the forks of the forklift. Thanks to this system, the driver has a clear view of the forks and other attachments, allowing the truck to be optimally positioned. Consequently, the forklift operator can insert the forks into the pallet openings more easily, quickly, and safely. This prevents goods or racks from being accidentally hit and products from being damaged or falling. The camera system thus reduces the chance of accidents and damage to the forklift or goods, preventing downtime.

SideEye

Use SideEye from Stoneridge-Orlaco and prevent blind-spot accidents. This camera and radar detection system actively alerts you when cyclists, pedestrians or other road users are present in the blind spot of your truck. SideEye is therefore ideal for increasing the safety of vulnerable road users in urban environments

SideEye™: Active Turn Assist System increases Blind-Spot Safety

Use SideEye from Stoneridge-Orlaco and prevent blind-spot accidents. This camera and radar detection system actively alerts you when cyclists, pedestrians or other road users are present in the blind spot of your truck. SideEye is therefore ideal for increasing the safety of vulnerable road users in urban environments.

To enhance the safety in the blind spot, camera and active detection systems are required in a growing number of countries. Starting March 1, 2021 in the United Kingdom, for example, vehicles over 12 tons must meet the Direct Vision Standard if they are to be allowed to drive into the London urban area. In the EU, new truck types must have a blind spot system in compliance with the General Safety Regulation from 2022. New vehicles must have such a system from 2024.

ForkView

Save valuable time and reduce the risk of accidents with the ForkView camera system for forklifts. This robust and compact camera-monitor system from Stoneridge provides perfect visibility of a forklift or reach truck's fork. By doing so, ForkView increases safety in the warehouse and saves time while moving goods.

Save valuable time and reduce the risk of accidents

The ForkView system is mounted on the inside of the fork. Thanks to its robust housing, the camera does not get damaged during the loading or unloading of pallets. With a viewing angle of 51 degrees, the camera provides visibility of both the left and right fork. On the monitor, the driver can immediately see if the fork is correctly positioned, allowing the forks to be accurately inserted into pallet openings at great heights. This prevents goods or shelving from being accidentally hit and products from being damaged or falling. The camera system thus reduces the likelihood of accidents and damage to the forklift or goods, preventing downtime. ForkView is suitable for reach trucks and side loaders, among others.

FrontView

Safe and effortless forward driving? Meet the FrontView camera-monitor system from Stoneridge. This system offers precise visibility of the area in front of a vehicle, even when visibility is obstructed by, for example, a load bin, goods, or other attachments. This reduces the risk of accidents and damage to goods, ensuring smoother operations and heightened safety.

Optimal Visibility with FrontView

Thanks to the monitor in the cabin, the driver can easily see what's happening directly in front of the vehicle. This not only enhances safety but also allows drivers to work more quickly and efficiently. FrontView from Stoneridge is particularly suitable for forklifts and earthmoving machines.

The FrontView system utilizes a FAMOS camera specifically designed to provide a broad and clear view of the area in front of the vehicle. The image from this camera is then displayed clearly and accurately on the RLED monitor. The analog FrontView system can be combined with other systems, such as RearView and RadarEye, for comprehensive visibility and enhanced safety.

Digital FrontView

Enhance the safety and ease of operation of forklifts with Stoneridge's Digital FrontView camera. This advanced system provides crystal-clear and accurate visibility of the area directly in front of the vehicle, even when visibility is obstructed by load bins, goods, or other front-mounted machines. With the improved visibility offered by Digital FrontView, the risk of accidents and damage to goods is reduced. Whether working in a busy warehouse, on a construction site, or in any other industrial environment, Digital FrontView makes maneuvering with a vehicle easier and safer.

Optimal and Real-Time Vision with Digital FrontView

A clear and unobstructed view of the situation in front of the vehicle is crucial when driving, especially when handling loads. Digital FrontView offers the perfect solution. The ELED monitor in the cabin displays real-time images from the EMOS camera, resulting in high-quality image clarity. This ensures that the driver has a sharp overview of what's happening in front of the vehicle, preventing accidents.

Our systems are highly robust and shock- and vibration-resistant, functioning under the most extreme conditions. They can withstand up to 50 G-forces, continue to operate in extreme temperatures (-30°C to 70°C), and are dust and waterproof (IP67 and IP69K).

View-on-Forks

Enhance precision and safety when moving goods with the View-on-Forks camera system for forklifts. This advanced camera-monitor system from Stoneridge offers perfect visibility between the forks of a forklift or reach truck. The camera's positioning allows drivers to track both forks in real-time, enabling them to pick up pallets in one go. This increases safety in the warehouse and ensures more efficient goods handling.

Work More Accurately with View-on-Forks

With View-on-Forks, drivers can perform their work with greater accuracy and confidence. The camera is mounted between the forks of the forklift. Thanks to this system, the driver has a clear view of the forks and other attachments, allowing the truck to be optimally positioned. Consequently, the forklift operator can insert the forks into the pallet openings more easily, quickly, and safely. This prevents goods or racks from being accidentally hit and products from being damaged or falling. The camera system thus reduces the chance of accidents and damage to the forklift or goods, preventing downtime.

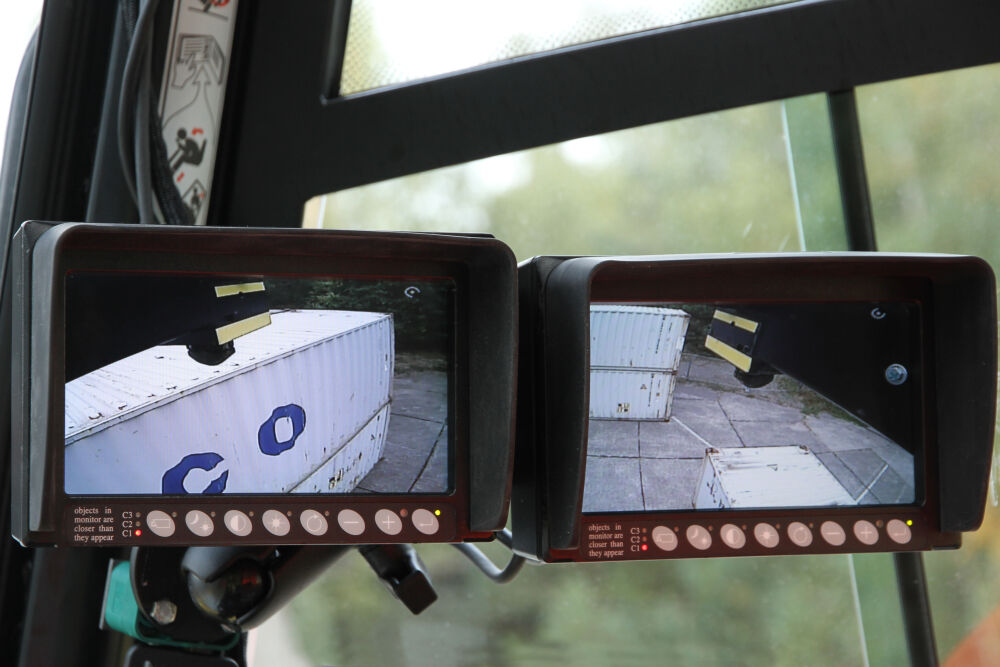

TwistLockView

TwistLockView is specifically developed for reach stackers and empty container handlers. When picking up containers, the correct positioning of twistlocks can be challenging due to limited visibility. With the advanced cameras of this system, the driver gets a clear view of both sides of the spreader, allowing for perfect alignment of the twistlocks and the spreader.

Enhanced Container Handling Precision with TwistLockView

TwistLockView is specifically engineered for reach stackers and empty container handlers, addressing the challenge of precise twistlock positioning during container handling operations. Limited visibility often complicates this task, but with the advanced camera system of TwistLockView, operators gain a comprehensive view of both sides of the spreader, facilitating precise alignment of the twistlocks.

Within the cabin, operators benefit from dual monitors displaying live camera feeds, ensuring clear visibility of each twistlock. Additionally, an alternative configuration offers a split-view option with a generous 12-inch monitor. This versatility empowers operators to optimize their container handling processes, mitigating the risk of accidents and enhancing overall operational efficiency. TwistLockView not only streamlines container handling procedures but also prioritizes safety and operator comfort, making it an indispensable asset for any container terminal or logistics operation.

SurroundView

Visibility around heavy machinery is often limited, with numerous blind spots around the vehicle. This can create potentially dangerous situations. The SurroundView system from Stoneridge provides drivers of heavy vehicles with a complete 360° overview around a vehicle, without any delay due to software-based image fusion. Thus, SurroundView contributes to the safety, efficiency, and comfort of the work environment.

Visibility around machines with Stoneridge's SurroundView.

The SurroundView system consists of four FAMOS compact cameras that eliminate blind spots. The cameras provide visibility on the front, rear, and sides of the machine. Through the Orlaco MultiView box, the four camera images are merged onto the robust Orlaco 7 or 12-inch monitor, creating one complete overview. Since no calibration is needed, the system is easy to maintain.

Thanks to the SurroundView system, persons and objects around the vehicle are always visible. The image on the monitor is displayed without any delay, allowing the driver to see in real-time what is happening around the vehicle. This system is universally applicable and suitable for articulated machines. As the camera images do not need to be merged on an ECU, the installation is straightforward, and replacements in the field can be easily managed. Moreover, SurroundView can be expanded with IR LED day-night cameras and sensors for even more functionality.

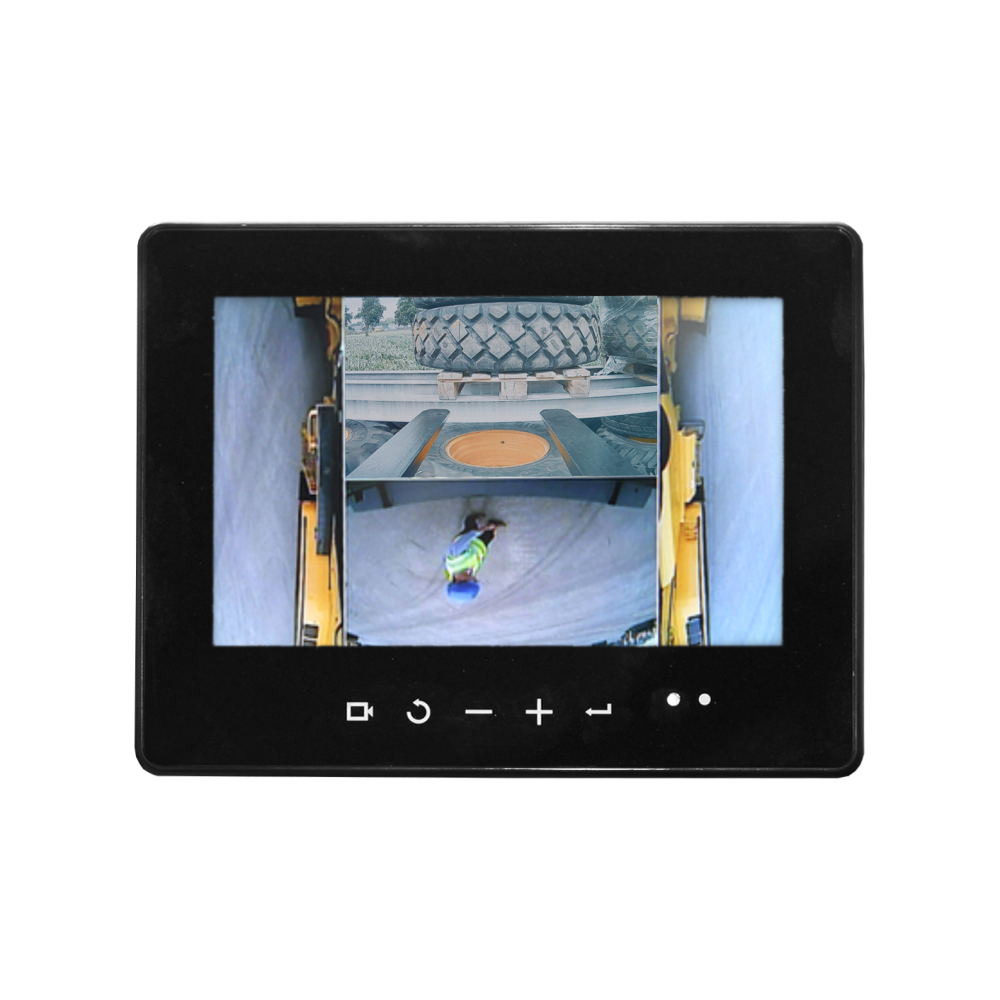

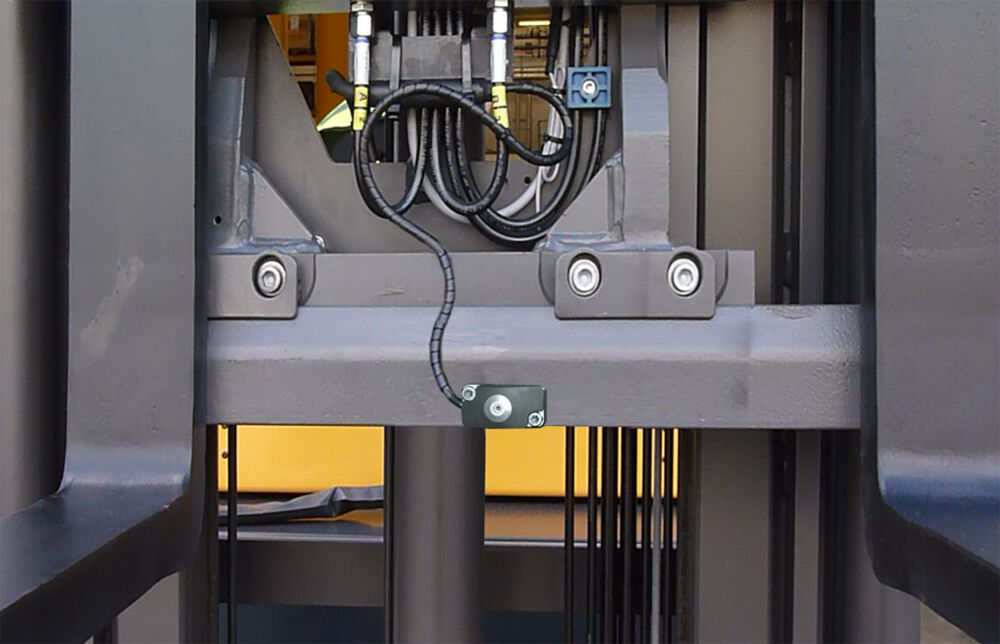

Digital Mid-Mast View

Digital Mid-Mast View is specifically designed for forklifts and reach trucks and offers operators a crystal-clear view of the working area without the need for drilling or welding on the forks. By installing a camera at the mid-point along the mast of the forklift, this system significantly improves visibility and safety during lifting operations, especially when the mast is partially or fully extended. This allows the driver to position the truck more accurately, reducing the risk of accidents and damage to the forklift or goods.

Premium high-definition camera system for forklift operators

Digital Mid-Mast View is specifically designed for forklifts and reach trucks, providing drivers with crisp visibility of the work area without the need for drilling or welding on the forks. By installing a camera at the midpoint along the mast of the forklift, this system significantly improves visibility and safety during lifting operations, especially when the mast is partially or fully extended. This allows the driver to position the truck more accurately, leading to a reduction in the risk of accidents and damage to the forklift or goods.

The Digital Mid-Mast View camera system is a combination of an EMOS camera and an ELED monitor, connected with a dynamic Ethernet cable. The ergonomically placed monitor enables the driver to look in a natural and comfortable way. This reduces strain on the neck and shoulder muscles, lowers the risk of sick leave, and increases productivity. Thanks to its waterproof and shock-resistant housing, the system performs reliably under extreme conditions and temperatures from -40°C to +85°C / -40°F to +185°F.

In addition to Digital Mid-Mast View, Stoneridge offers various alternative visibility systems for forklifts. Depending on the application, the driver's preference, and the type of forklift, choices can be made among View-on-Forks, ForkView, or Mid-Mast View (analog).

Find a dealer

Find our Orlaco dealers in over 35 countries worldwide. They are there to support you!

Contact Us

Every mining vehicle deserves the best visibility solution. With Stoneridge's systems, navigate with confidence, efficiency, and, above all, safety. Discover today how our solutions can revolutionize your mining operations.

- Made in Holland

- Global services

- Cameras for extreme conditions

- Certified production processes

Products

Our products are sold through our global Orlaco Dealer Network. Thanks to this network, we can offer our products and provide service to end-users and the aftermarket worldwide. Our dealers, supported by direct assistance from Stoneridge and local expertise, ensure that end-users receive the best advice. Find a dealer near you using our 'Dealer Locator'.

Are you working for an OEM (Original Equipment Manufacturer)? Then please contact us through the contact form on our website to get in touch with one of our account managers.

In addition to Orlaco Vision Systems, Stoneridge offers the MirrorEye Camera Monitor Systems for trucks, buses and coaches. Our technologies are driving the future of advanced vision systems for commercial vehicle applications. Stoneridge’s MirrorEye® Camera Monitor System replaces traditional rear and side-view mirrors with digital cameras and monitors, delivering greater safety, and enabling fuel efficiency and reduced emissions. Learn more about our MirrorEye portfolio at www.stoneridge.com/mirroreye.

No, we do not offer Ex-cameras.

No, we do not offer underwater cameras.

Orlaco camera systems are fully compatible with HMI systems. Integration typically occurs between the end user and the HMI integrator or supplier, with Orlaco providing the necessary hardware.

Stoneridge does not have an online shop for Orlaco products. Our products are sold through our global network of Orlaco dealers. Thanks to this network, we can offer our products and provide service to end users and the aftermarket worldwide. Our dealers, with direct support from Stoneridge, ensure that end users receive the best advice, customer service and support. Find a partner near you through our 'Dealer Locator'.

Our products are sold through our global Orlaco Dealer Network. Thanks to this network, we can offer our products and provide service to end users and the aftermarket anywhere in the world. Find a dealer near you via our 'Dealer Locator' and contact us for more information about the prices of Orlaco Vision Systems in your region.

Our products are sold through our global Orlaco Dealer Network. Thanks to this network, we can offer our products and provide service to end users and the aftermarket anywhere in the world. Find a dealer near you via our 'Dealer Locator' and contact us for more information about the delivery time of Orlaco products in your region.